Overview

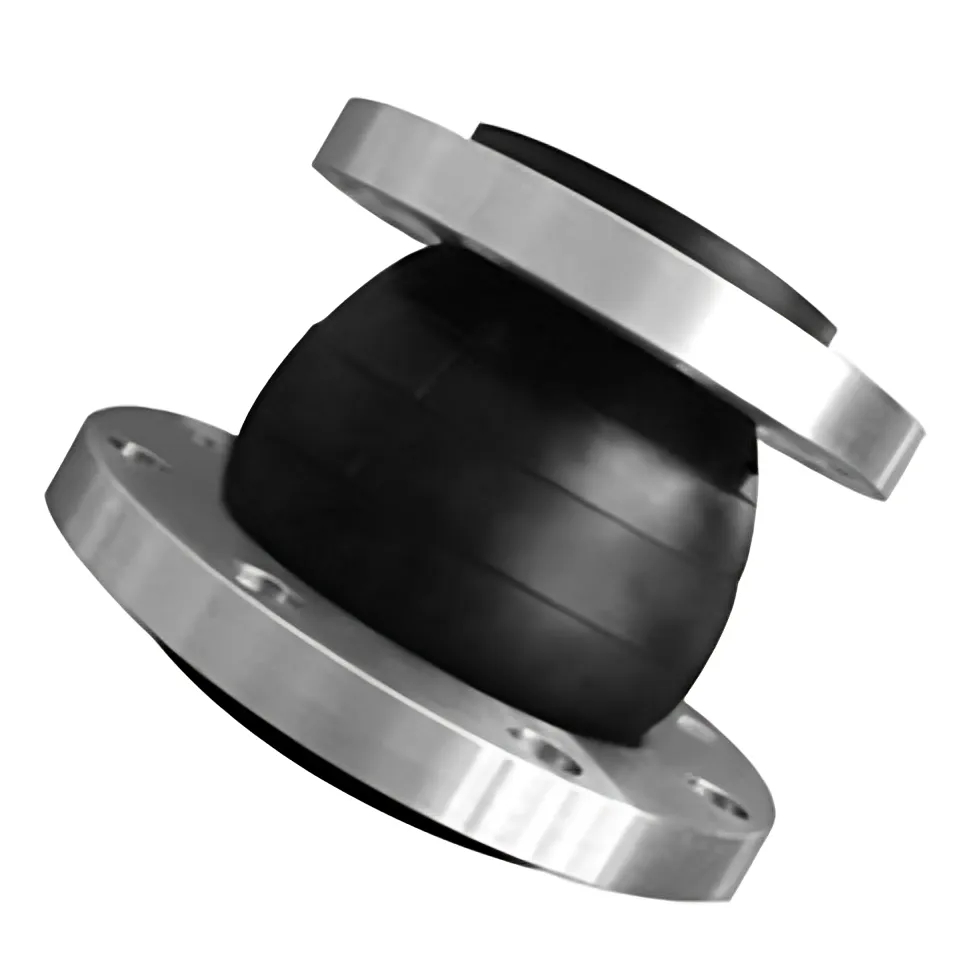

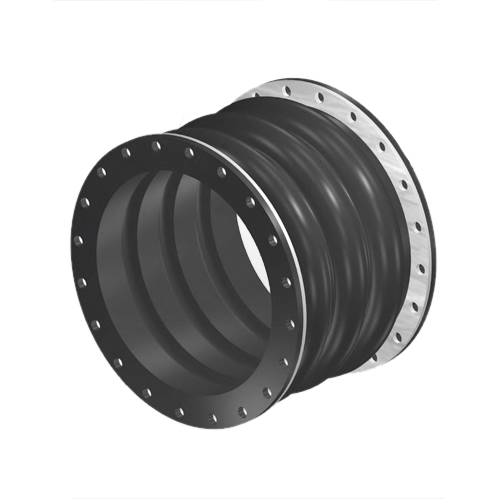

DEVEL expansion bellows have been designed to control vibration, reduce noise, relieve stress, prevent system shock and compensate for misalignment and movement. Use of braided metal connectors for applications such as pumps, compressors, and other mechanical equipment will enhance the overall operation of the system.

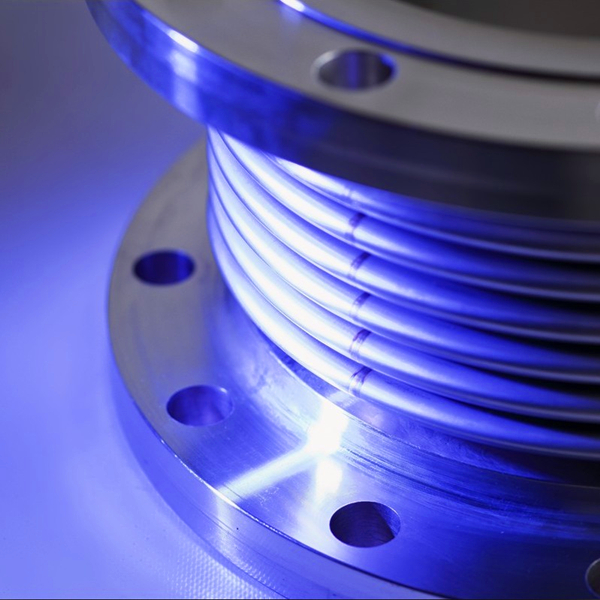

Flexible metal hose by itself, when subjected to high pressure can over-extend past the ability to operate properly. It is necessary, therefore, to include an external flexible restraint (i.e., braid) to withstand the specified internal pressure and prevent excessive elongation. Braid, (woven metal) is designed to fit snugly over metal hose and is fastened to the ends of both hose and fittings. This braid is designed to be strong enough to withstand elongation for the full pressure rating of the hose.

Flexible metal hose and braid can be made from a variety of different metals to meet industry needs. Specification of the hose and braid is determined by temperature, pressure, flow media, application and external environment. Common materials used for braided flexible metal connectors are 321 stainless steel hose and a 304 stainless steel braid and are carried in stock by DEVEL products. The products contained in this catalog are representative of the typical sizes, lengths and materials found for pump connectors; however, other materials and lengths are available and can be ordered per customer specification.

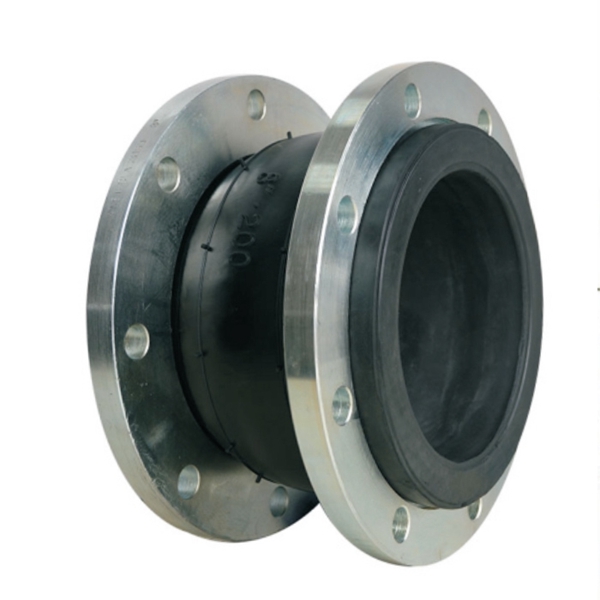

Description

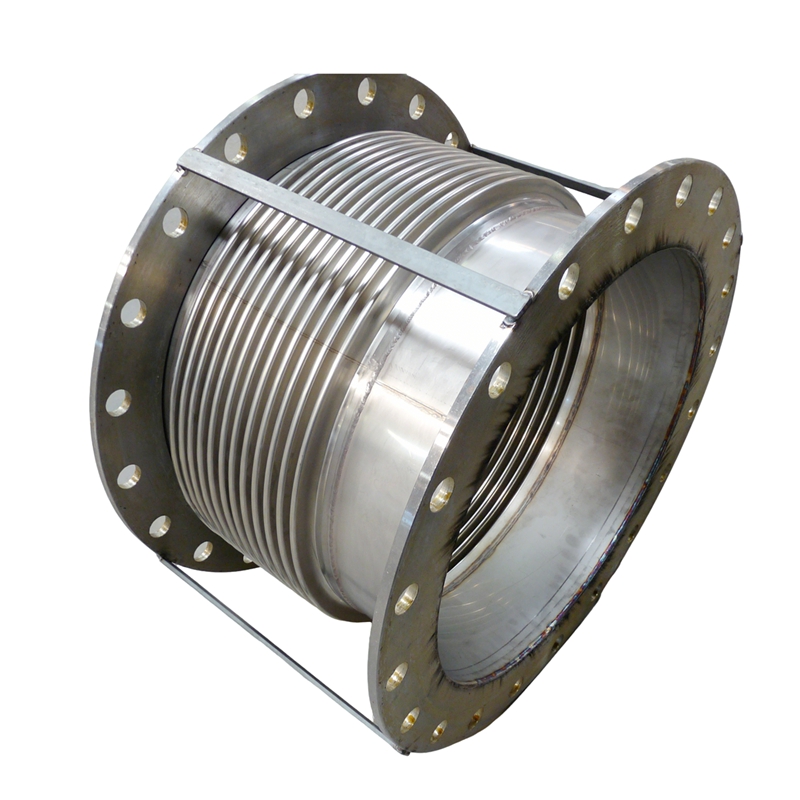

DEVEL's expansion bellows Series EBF521 are specifically designed for piping applications requiring limited absorbtion of axial and lateral movements. Where small thermal movements are involved and proper anchoring and guiding is feasable,DEVEL's Single-Flex "EBF" series expansion joint system provides the most economical installation. Single-Flex is the base member of DEVEL metal expansion bellows family, consisting of a bellows element and end fittings.

flange adaptor.jpg)