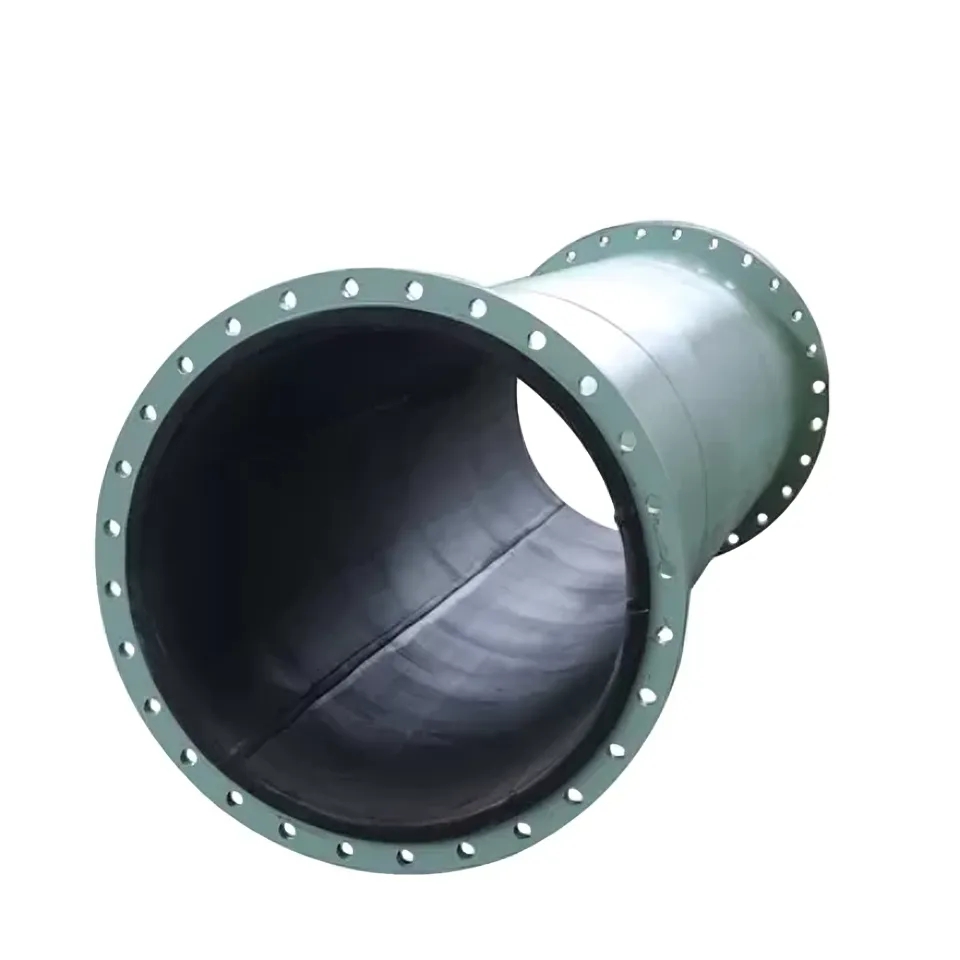

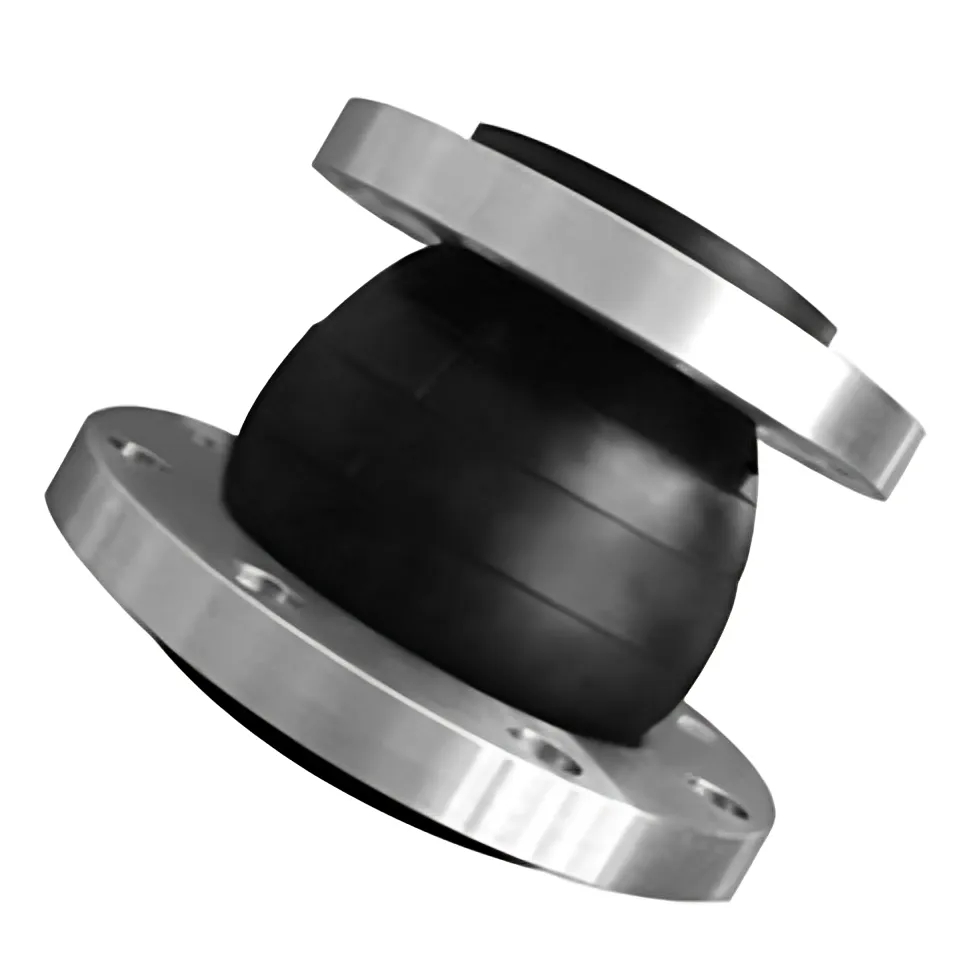

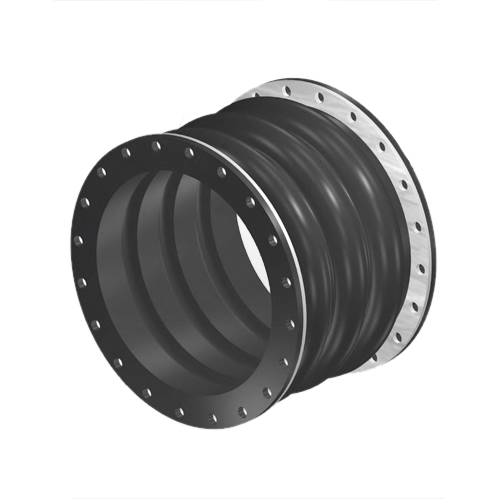

DEVEL rubber lining craftsmen have the skill and experience to rubber line the most difficult projects. The ability to rubber line any fabrication in our facility that can be legally transported on any highway with an oversize shipping permit gives the end user a larger savings on their budget. DEVEL also offers a complete field lining service at your plant for those projects to large to ship. Our head engineer had been trained in the Japanese rubber lining company for 30 years.

There is a wide variety of materials used in the rubber protection industry. The type of rubber protection is specific to each separate application. Rubbers to inhibit abrasion, and corrosion from harsh chemicals include: Naturals, Gum, Neoprene, EPDM, Nitrile, Ebonite, Hypalon, Triflex, MOR and Chlorobutyl. These rubbers come in different thicknesses and durometers (a measure of how hard the rubber is after being cured). Durometer ratings are critical in the rubber lining applications where abrasion and wear is a concern. DEVEL rubber lining team has the experience and skill set to apply and cure all of the rubbers listed above.

Advantage of rubber lining:

l High impact resistance;

l Good anti-abrasion;

l Fine anti-corrosion;

l Adapting to wide range of temperature;

l Less running resistance can reduce energy consumption;

l Good steel pipe;

l Light weight, easy to install, maintain and transport;

l Recycling and reusing.

Using field:

l Nuclear power

l Coal power plant

l Ion exchangers for watertreatment plants

l Ship building

l Offshore industry

l Chemical industry

l Metal industry

l Mining industry

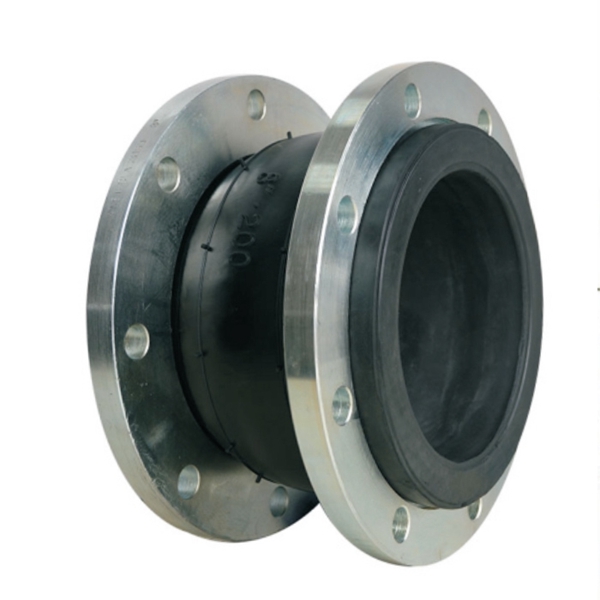

flange adaptor.jpg)