Advantage

1.Long lifespan,more than 50 years under normal condition.

2.Good corrosion resistance.

3.Good crack growth resistance.

4.Little coefficient of friction and low flow resistance.

5.Excellent wear resistance, its wear resistance is 4 times higher than steel pipes under normal conditions.

6.Good solder ability,its interface strength is higher than the pipe body.

7.Good flexibility and anti-scratch ability.

8.Very high impact resistance.

9. The unique resistance to low temperature, workable at temperature - 40-60 °c.

10. Light weight, 1/8 weight of steel pipe, easy for transportation and installation.

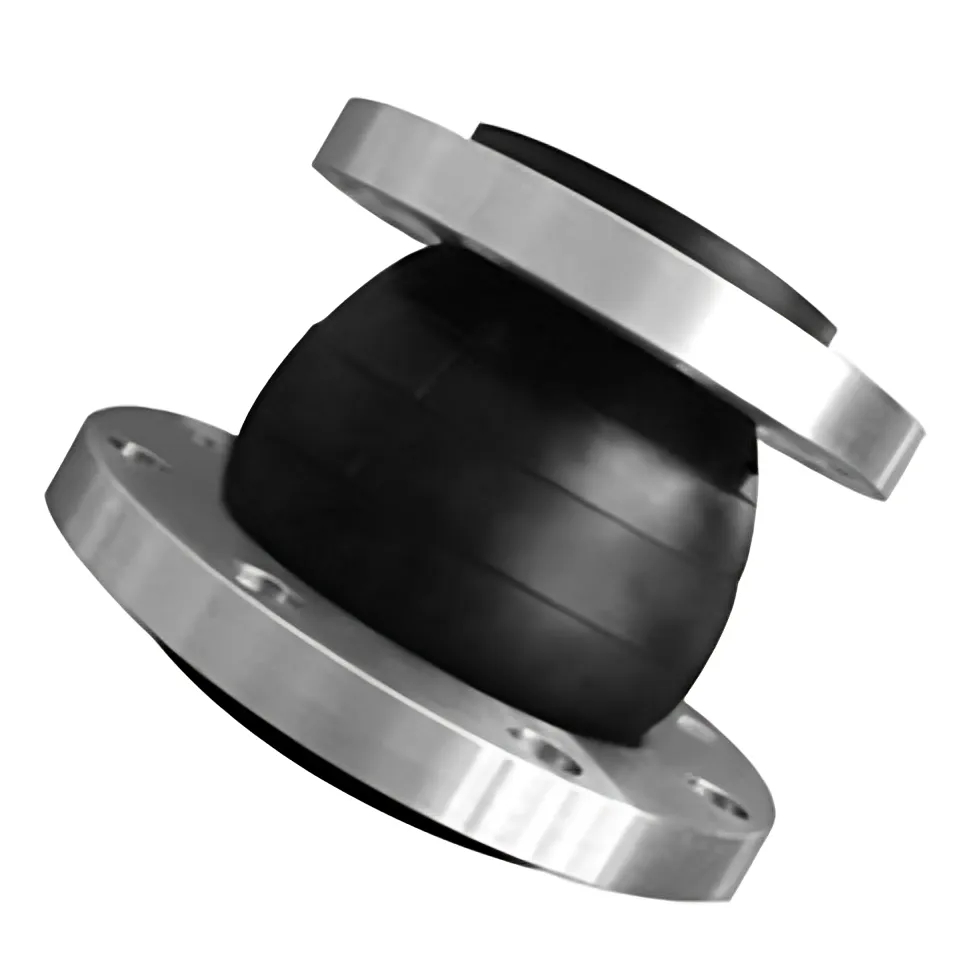

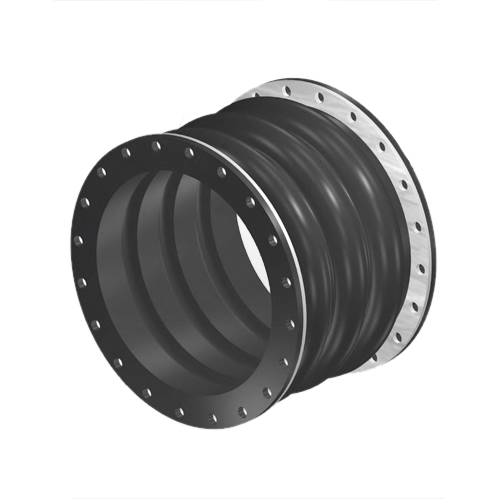

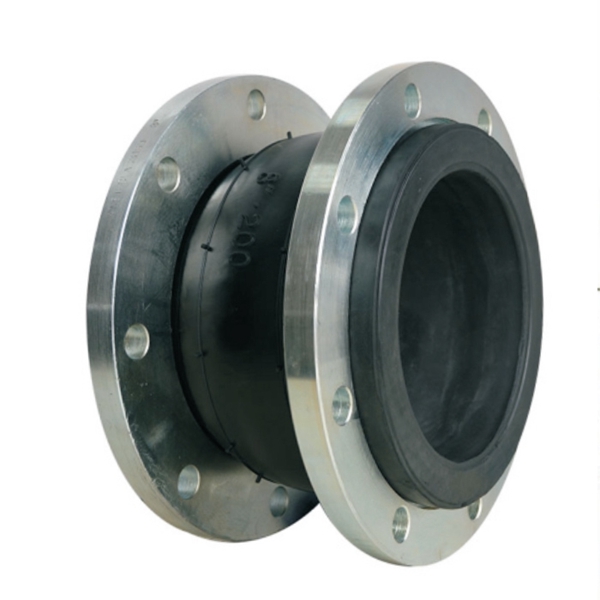

11. Flexible metal flange for connection, easy for installation and disassembly.

Applications

1. Used for mud piping of dredge.

2. Widely used for sucking or discharging of mud,water, oil, air, and Powered in Industry, agriculture, factory, mining and building etc.

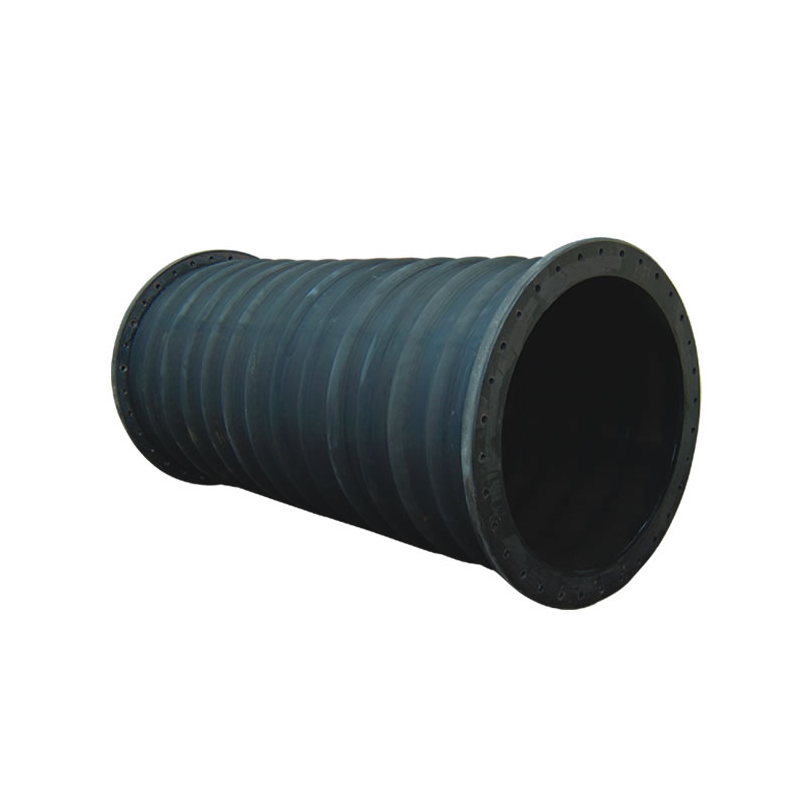

Materials

Tube: Smooth NR/ synthetic rubber, generally color is black

Reinforcement: one or multilayer spiral fabric reinforcements, steel wire spiral layer,

Cover: Oil, abrasion and weather-resistant wrapped synthetic rubber.

Structure

1. The inner rubber liner is composed of wear-proof natural rubber and synthetic rubber

2. The reinforcement layer is composed of high strength rubber dipped chemical fiber and reinforced by spiral metal wire.

3. The rubber cover is composed of natural rubber and synthetic rubber.

4. The surface of the hose takes the shape of corrugated

Performance

1. Rubber hose pipes are used with dredgers for silt/gravels conveyance.

2. Pipe wall thickness range: from 20mm up to 50mm.

3. The suitable working temperature: from -20°C to +50°C.

4. Abrasion-resistant and bending –resistant.

5. It is convenient to install, flexible to use and safe.

flange adaptor.jpg)